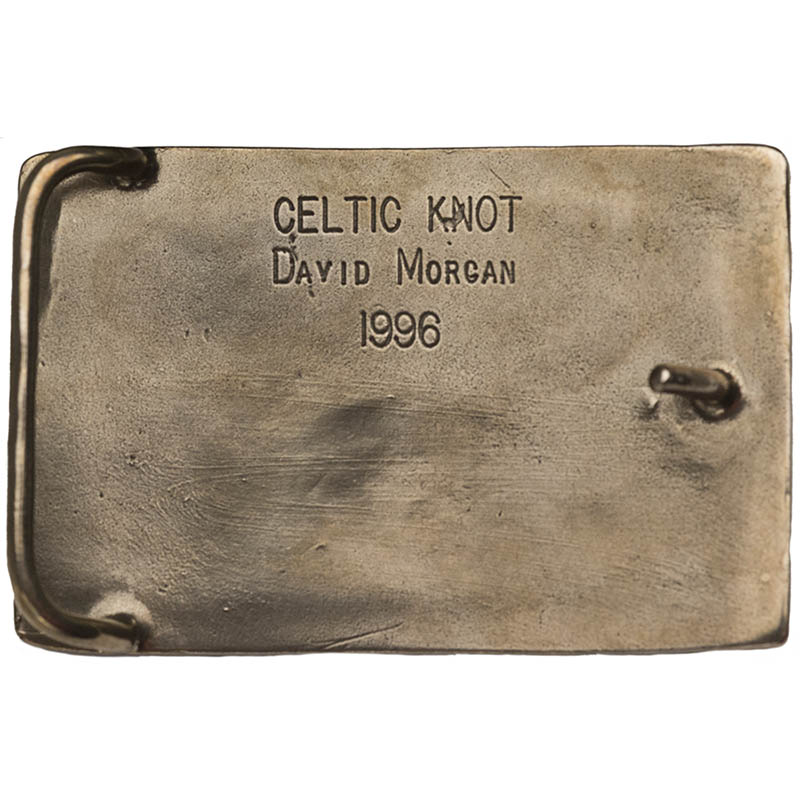

Celtic Knot Belt Buckle, Bronze

The Celtic knot on this solid bronze buckle is done in high relief, an intricate rendering of the endless ribbon of eternity. The buckle fits 1½ inch belts, such as our 1½ inch Bridle Leather Belt. The buckle size is 2-15/16 x 1⅞ inches. Made in USA.

The Celtic knot on this solid bronze buckle is done in high relief, an intricate rendering of the endless ribbon of eternity. The buckle fits 1½ inch belts, such as our 1½ inch Bridle Leather Belt. The buckle size is 2-15/16 x 1⅞ inches. Made in USA.

-

More Info

Our Celtic Knot Belt Buckle is Back! This buckle, designed by our own David Morgan, was our most popular buckle for many years. In 2017 the company who cast these buckles for us closed their doors. Just this winter we learned that Rick Geib at Fluidbronze, who casts our Wildlife in Bronze jewelry, had increased his casting capabilities and could cast these buckles for us. We are delighted.

These belt buckles are cast in bronze or solid sterling silver using the "lost wax" investment casting method. Each buckle made in this age-old jeweler's technique must first be made in wax. The wax buckle is then "invested" or covered with a plaster of paris slurry and allowed to dry. It is then placed in a computer controlled electric kiln that slowly ramps up the temperature, eventually reaching 1500 degrees Fahrenheit for several hours hours before dropping back to 900 degrees. This process takes about 22 hours. During this process, all the wax in the plaster mold is burned out or "lost", the result is a cavity into which the molten metal is poured in. The 900 degree plaster mold is placed in a vacuum chamber and a powerful pump draws a vacuum on the hot plaster mold as the metal is poured in. This vacuum process creates greater detailed castings with a minimum of feeder gates to the piece. After cooling, the buckle casting is broken from the mold. At this point, the casting is black from the oxidation of the molten bronze or sterling silver and must be carefully ground, tooled and polished to achieve the final gleaming finish. The final finishing and tooling marks reflect the individuality of each buckle and attests to the craftsmanship involved in its unique creation.