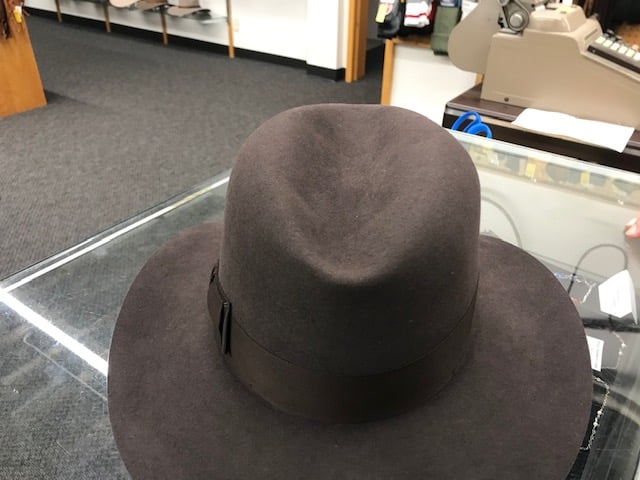

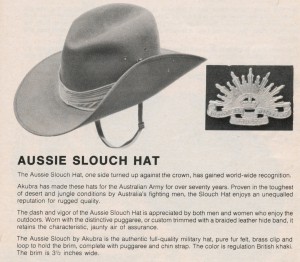

When you hold an Akubra, you’re not just holding a hat—you’re holding a physical piece of Australian heritage. Each one is the result of a meticulous six-week process, involving over 60 skilled hands at the Kempsey factory. This dedication to craftsmanship ensures that every hat is built to endure.

For over a century, Akubra has been a symbol of the Australian outdoors. First worn by stockmen, drovers, and cattle station workers, the hat quickly became a fixture of rural life—not just for its durability, but for the sense of identity it carried. It shaded long eyes during long days under the sun and held up to years of hard use on the land. Over time, Akubra found its way from cattle stations to city streets, from war memorials to Olympic podiums, without ever losing touch with its roots.

The journey begins with rabbit fur, chosen for its unique combination of softness, strength, and water resistance. Unlike wool or synthetic blends, rabbit fur felts tightly and evenly, creating a dense, durable material that stands up to the harshest weather. It’s this quality that gives Akubra hats their trademark longevity and comfort. The fur is cleaned, blended, and formed into a cone shape where—through moisture and heat—the fibers are interlocked into felt. The felt is then dyed, shaped, and treated to handle years of wear in the sun and rain.

The final stages involve precise shaping, trimming, and finishing touches. Each hat is carefully inspected to meet Akubra’s high standards. This attention to detail is why Akubra hats are not only stylish but also incredibly rugged, capable of lasting decades with care.

For a closer look at this intricate process, check out this segment from ABC Landline:

How Akubra hats are made: inside Akubra’s Kempsey workshop